3-D printing alludes to processes in which material is joined or hardened under PC control to make a three-dimensional object. With a material being included, for example, fluid atoms or powder grains being intertwined. 3-D printing is utilized as a part of both quick prototyping and additive manufacturing. Articles can be of any shape or geometry. And regularly are created utilizing advanced model information from a 3-D display or another electronic information source, for example, an Additive Manufacturing File more often than not, present in consecutive layers. There are a wide range of advancements, as Stereo lithography or Fused Deposit Modeling. In this way, dissimilar to material expelled from a stock in the customary machining process. 3-D printing or additive manufacturing constructs a three-dimensional protest from PC helped configuration model or Additive Manufacturing File, for the most part by progressively including material layer by layer.

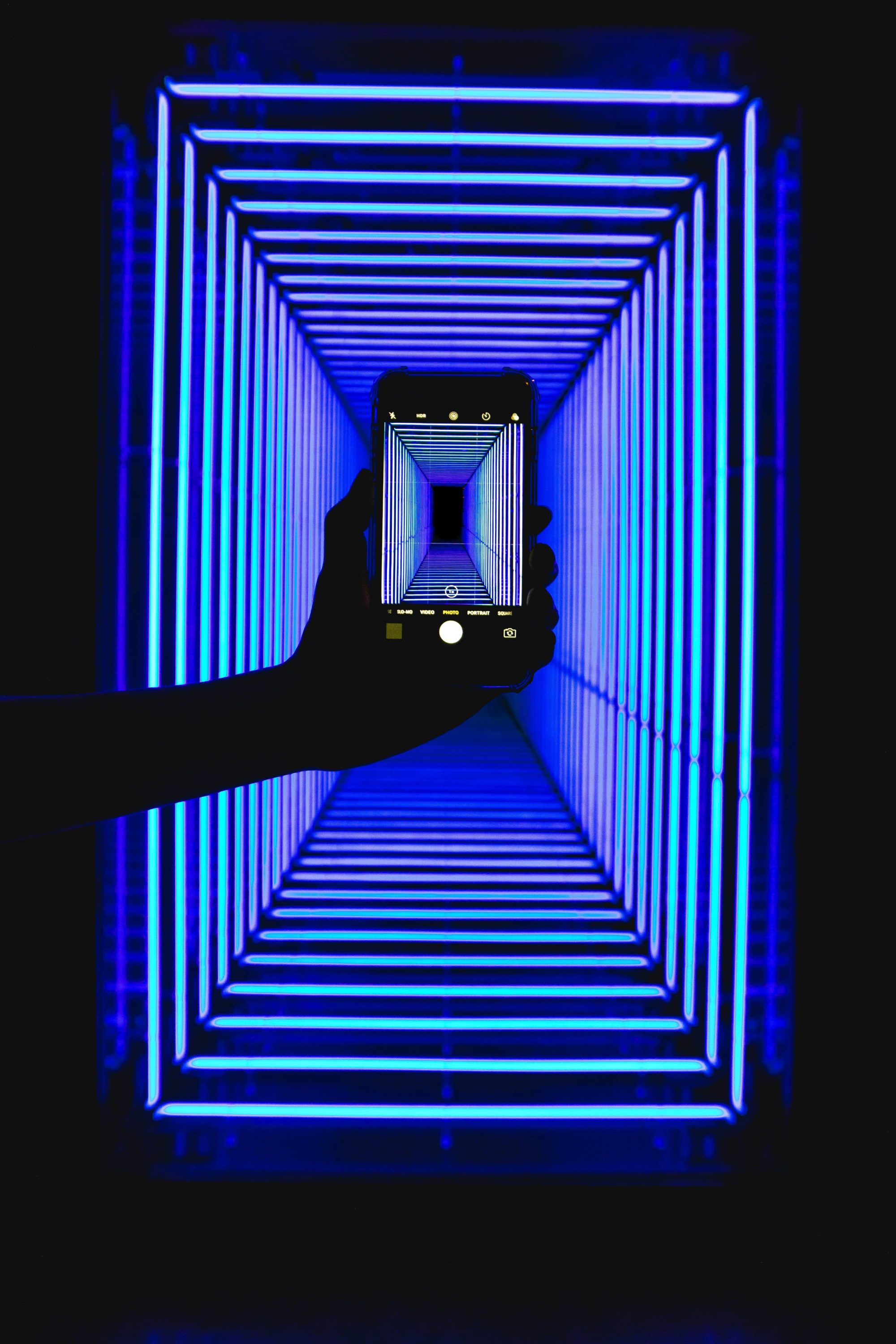

Source: Unsplash

A few key advantages of 3-D printing are that 3-D printing enables thoughts to grow speedier than ever. Having the capacity to 3-D print an idea that day it was composed shortens an improvement procedure from what may have been a long time to a matter of days. Helping organizations remain one stage in front of the opposition. Moreover, one thing you can’t get from a picture or virtual prototype on the computer screen is the way something feels in your hand. If you want to ensure the functional physical design and overall working of a product is just right. You must actually hold it, use it and test it. One more key feature that 3-D printing provides is that having the capacity to test thoughts rapidly and find what doesn’t work quickens disclosure prompting to a perfect solution. 3-D printing enables a product designer to make leaps forward at the beginning of the process, that are generally inexpensive allowing better items and more affordable deadlocks.